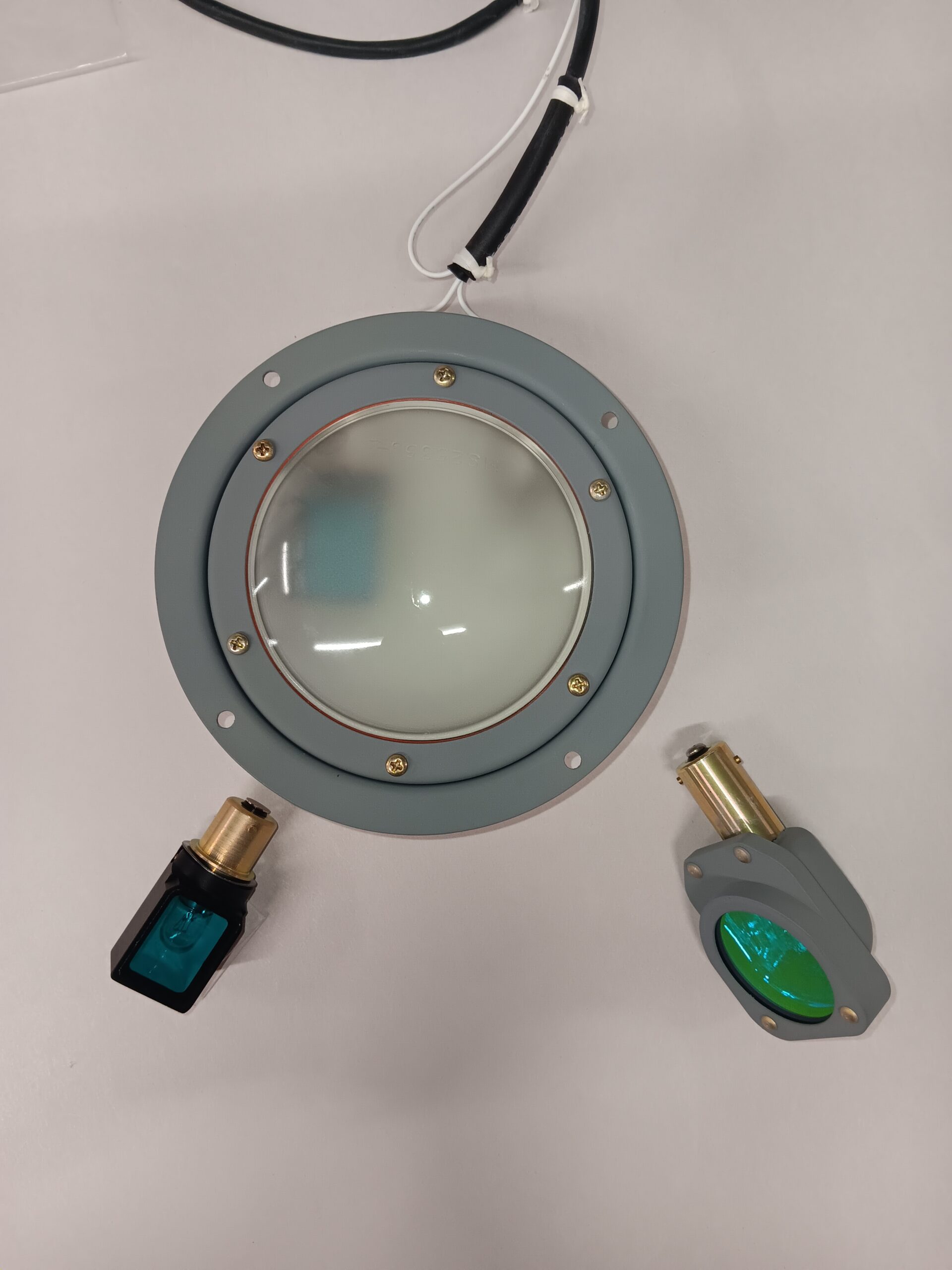

CPC manufactures a multitude of Interior lighting solutions including floodlighting, NVIS compatible overlays, map lights, and dome lighting. Crew stations must be illuminated with light that will allow the operator to clearly view the instruments, panel and indicator light under the NVISs, however the light should not interfere with the performance of the NVISs to amplify the low light nighttime scenes outside the aircraft, i.e. NVIS Compatible lighting.

Interior Lighting

Interior Lighting

Product Description

Floodlight Hoods, Filter Assembly and Floodlight Assembly were qualified to:

- Dielectric Strength MIL-L-6723B Para 4.4.2.8 modified to 1000 volts rms

- Gun Firing Vibration MIL-STD-810B Method 514.1, Procedure I & 16PS011E

- Temperature Low MIL-STD-810B Method 502, Procedure I • Temperature

- High MIL-STD-801B, Method 510, Procedure I

- Humidity and Moisture MIL-STD-810B, Method 507, Procedure I

- Salt Fog and Spray MIL-STD-810B, Method 509, Procedure I

- Sand and Dust MIL-STD-810B, Method 510, Procedure I

- Finish MIL-A-8625, Paragraph 3.7.1.2

The Floodlight Hoods, Filter Assembly and Floodlight Assembly were also qualified by the U.S. Air Force to 16PS011E.

- Vibration testing MIL-STD-810E, Method 514.4, Procedure Category 5

- Mechanical Shock Test MIL-STD-810E, Method 516.4, Procedure I and II

- Temperature Test (storage) MIL-STD-810E, Method 501.3

- Temperature Altitude MIL-STD-810E, Method 500.3, Procedure II

- Temperature Shock MIL-STD-810E, Method 503.3, Procedure I

- Sand/Dust Test MIL-STD-810E, Method 510.3, Procedure I

- Salt Fog MIL-STD-810E, Method 509.3 Procedure I

- Fungus MIL-STD-810E, Method 508.2

- Acceleration MIL-STD-810E, Method 513.3, Procedure II

- Humidity MIL-STD-810E, Method 507.3, Procedure I Cycle I

- Shock MIL-STD-810D, Method 516.3, Procedure I

- Explosive Atmosphere MIL-STD-810E, Method 511.3, Procedure I